Precision 3460 - Lots of cutting

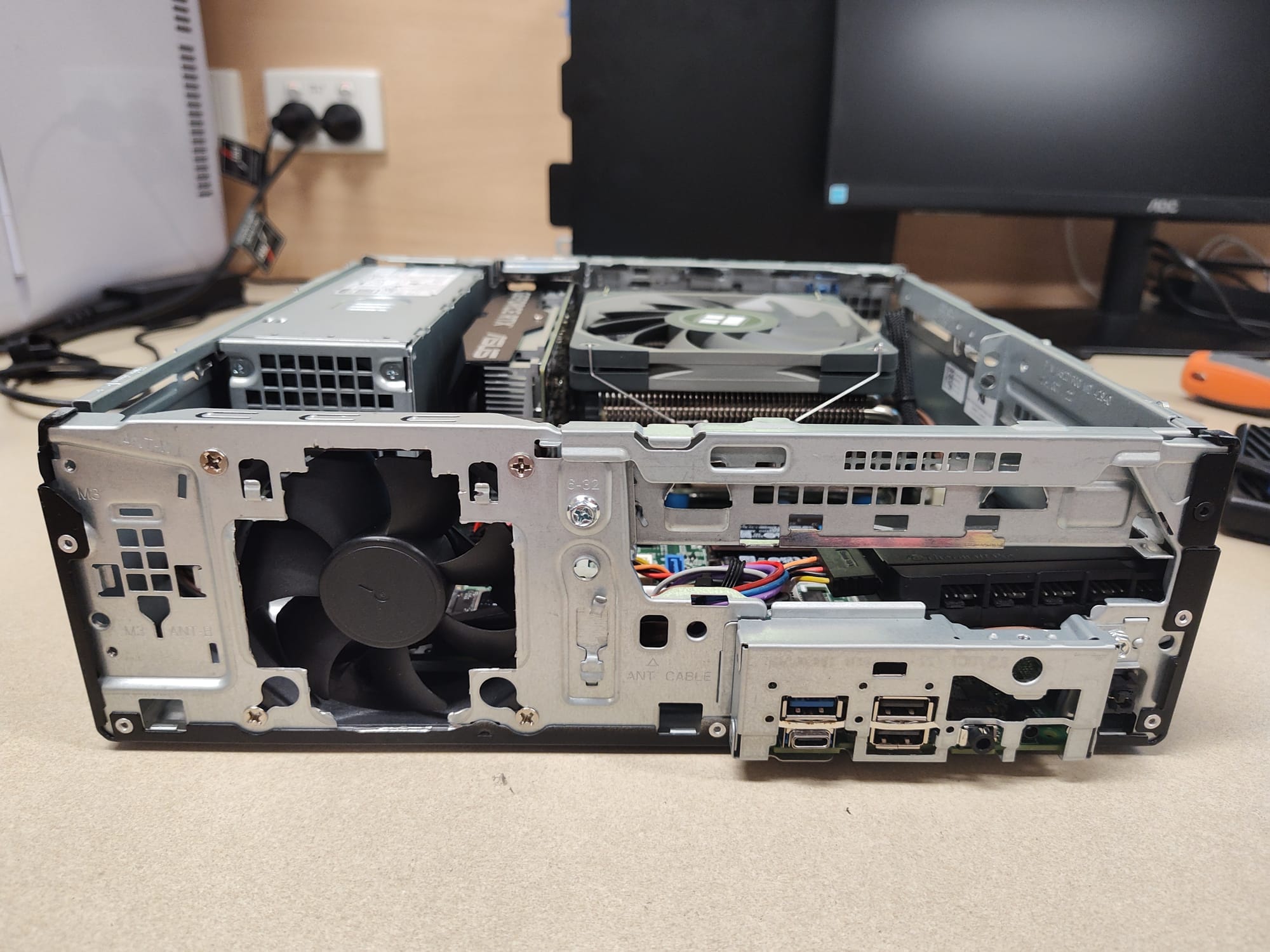

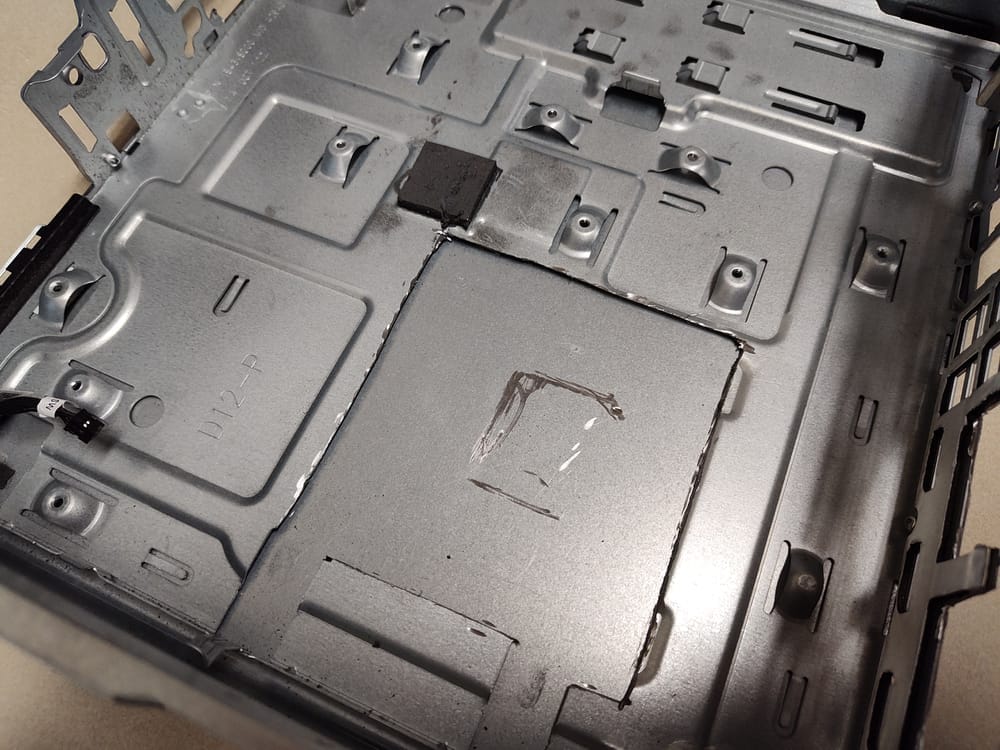

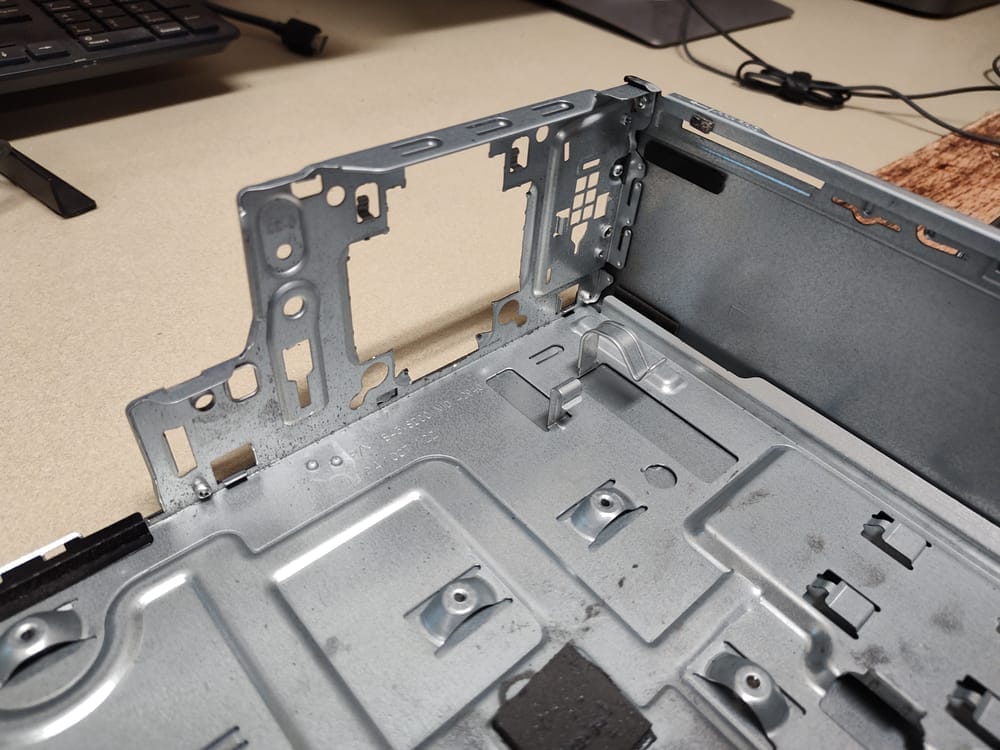

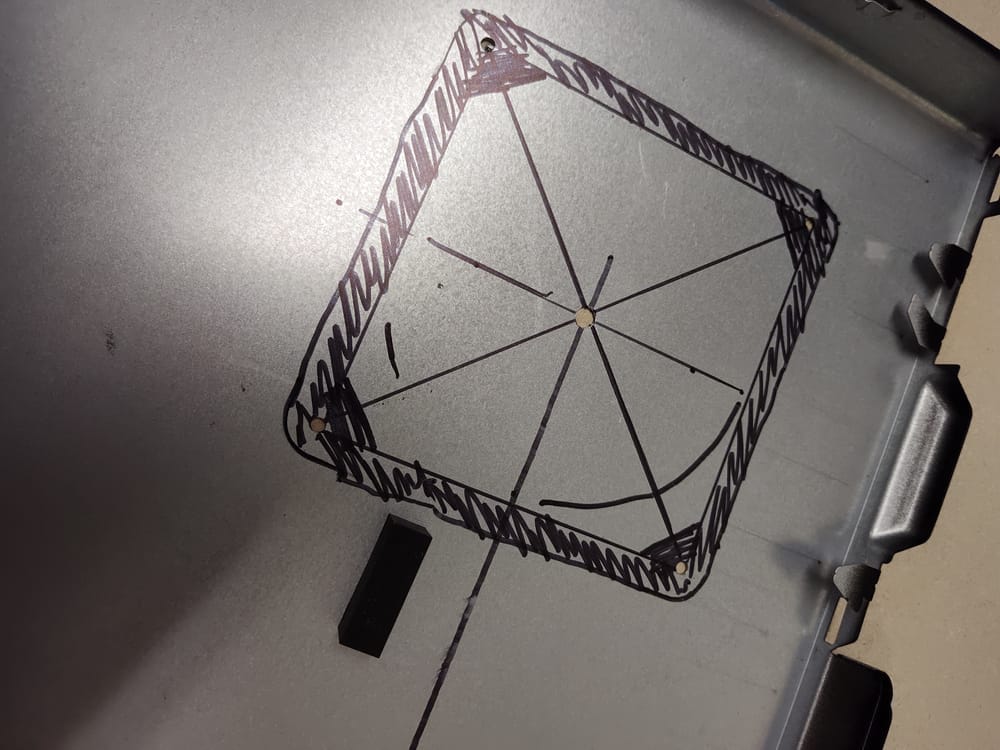

Back again with another update on my 3460. I've been doing some cutting with the dremel to make room for the backplate and I'm glad to report that after (carefully) cutting the inner metal while avoiding the back panel the motherboard now sits in place perfectly with no flexing when screwed in.

While examing the construction of the case I considered drilling out the rivets that hold the inner metal shell to the outer black painted outer case but decided against this because I know I'd struggle to get the right rivets and put it back together just right (though painting the inner steel except where the motherboard screws are a nice black with some red aluminum rivets would look very slick). It would have made cutting at least 73.2% easier. This wasn't all I cut.

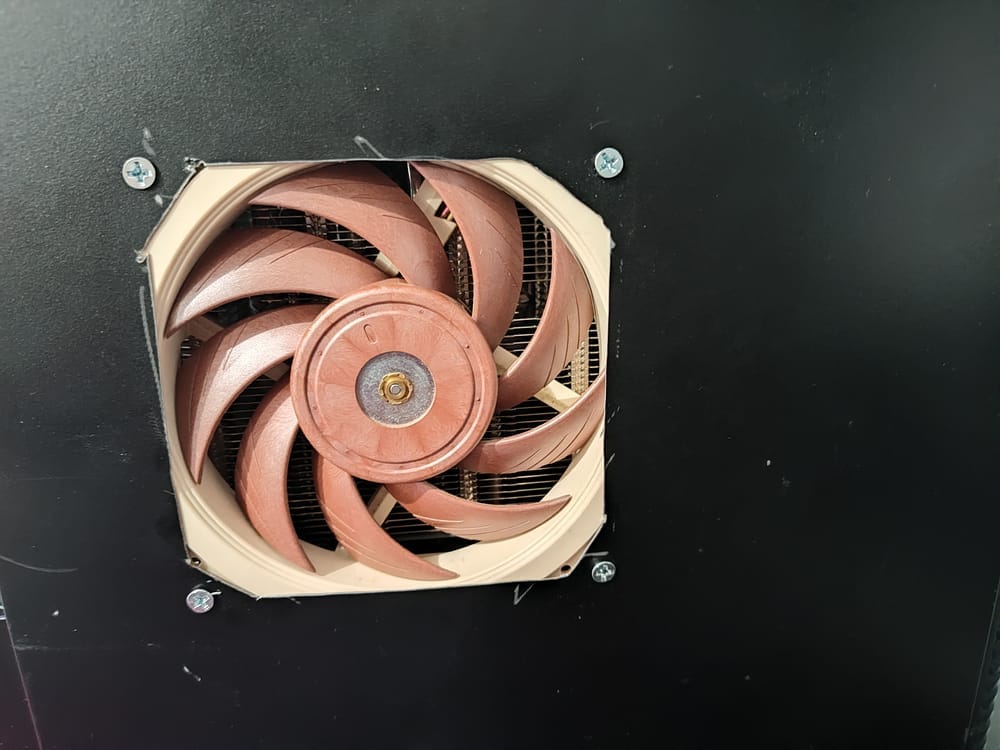

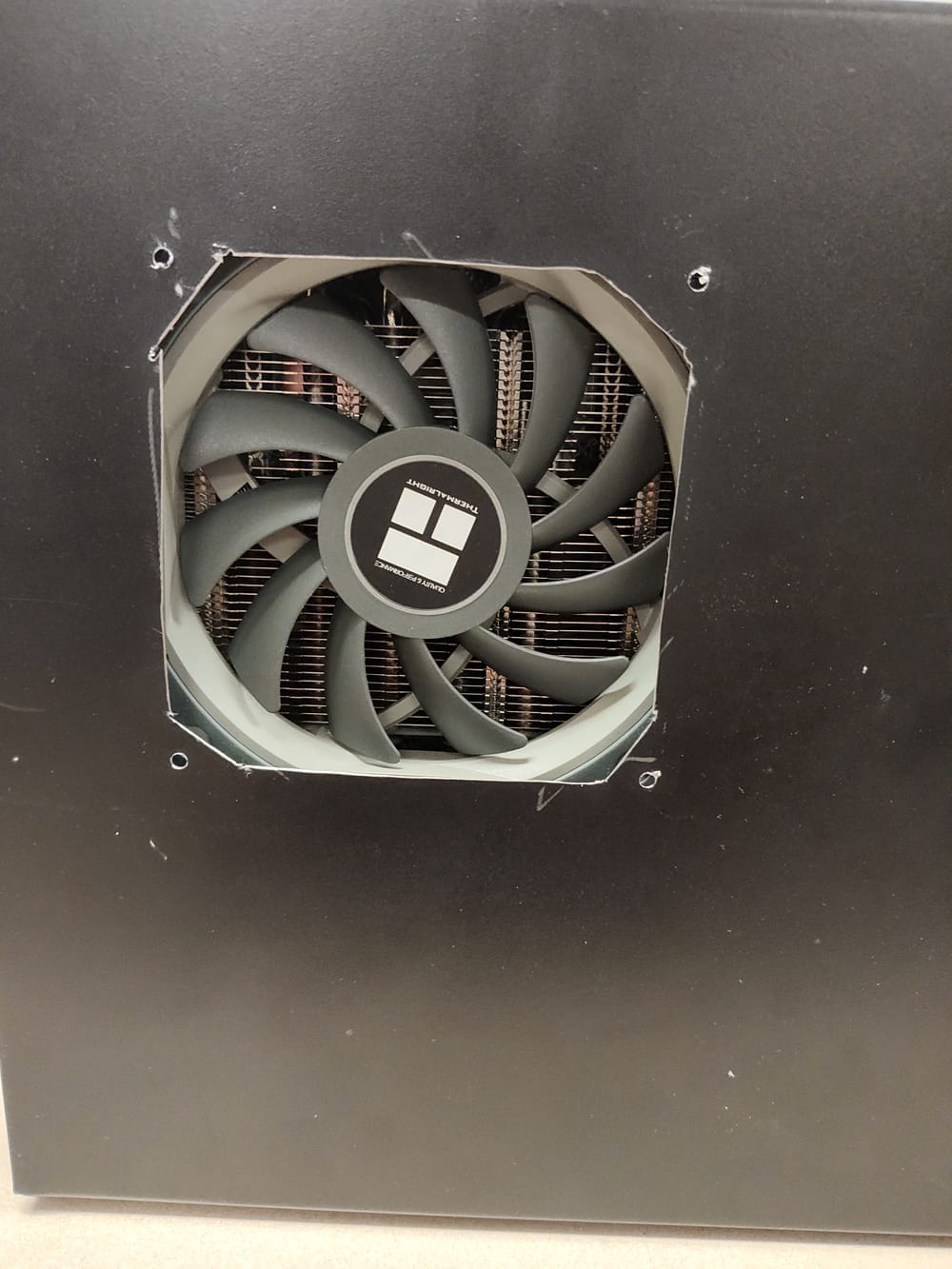

Here's something I wasn't anticipating. Earlier in this project I looked at 25mm (standard height) 120mm fans for the CPU heatsink in hopes of a higher airflow solution but they would not fit. After looking into the subject there was exactly one fan that I thought I could squeeze in with a 20mm height (this one and nearly all slim profile 120mm fans are 15mm tall) but wasn't thrilled about it.

Imagine my surprise then, after removing the 8 rubber anti vibration pads from the corners of a spare Noctua 120mm I had lieing around, that I could screw the fan straight into the panel and have it just slide over the heatsink with maybe 1mm to spare. This is great because I'll have something to screw the fan filter into when it arrives.